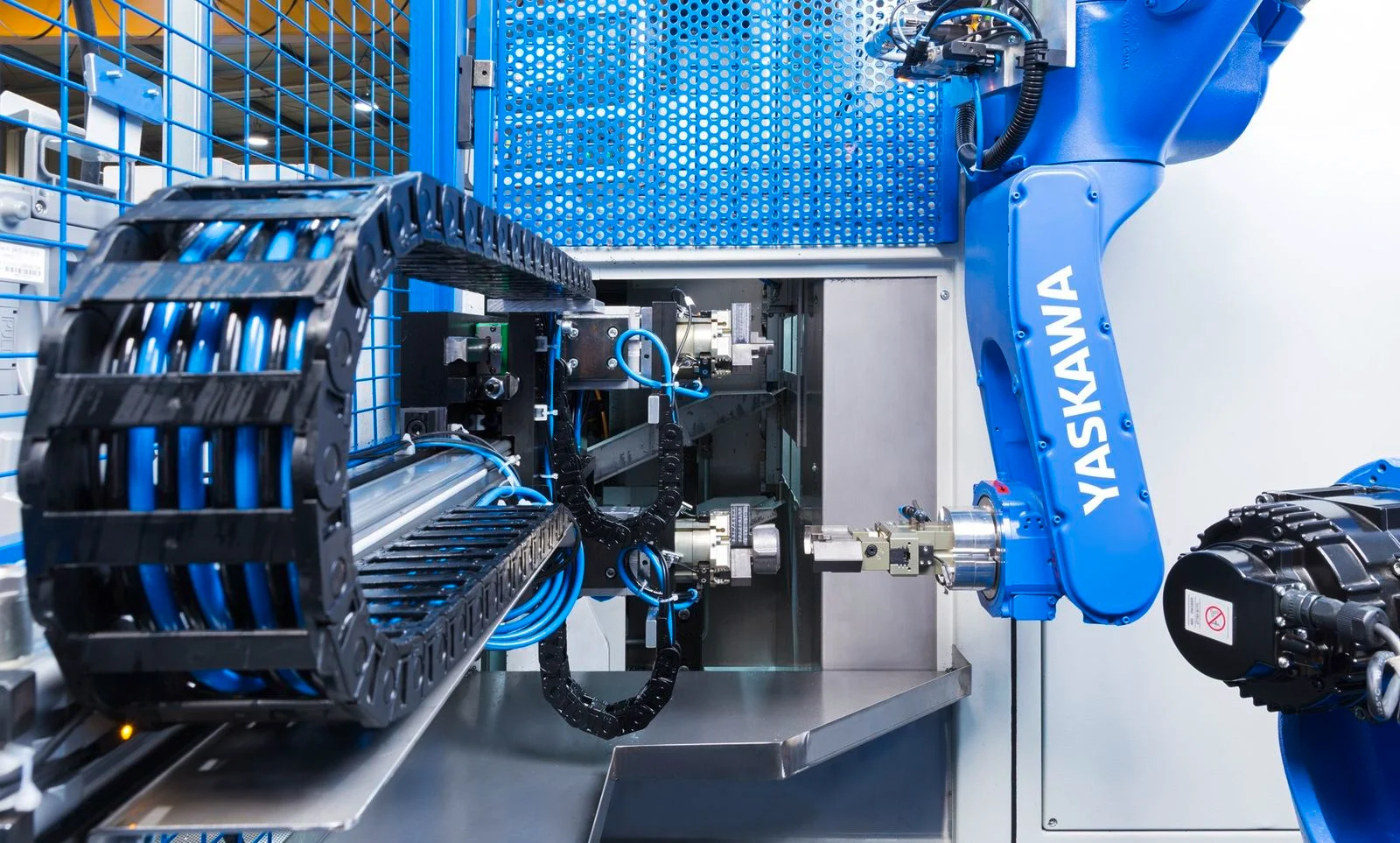

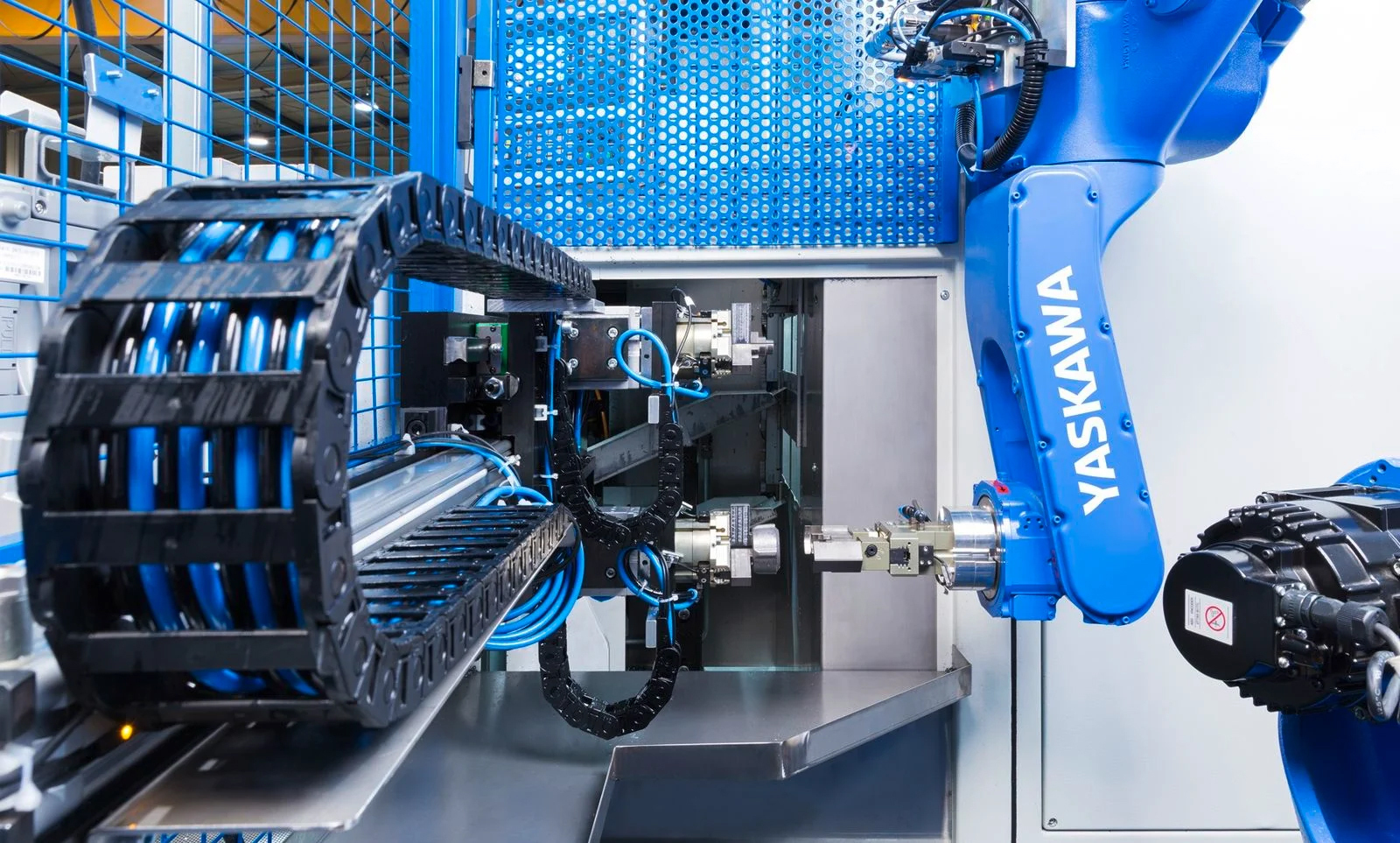

Robotic Cell

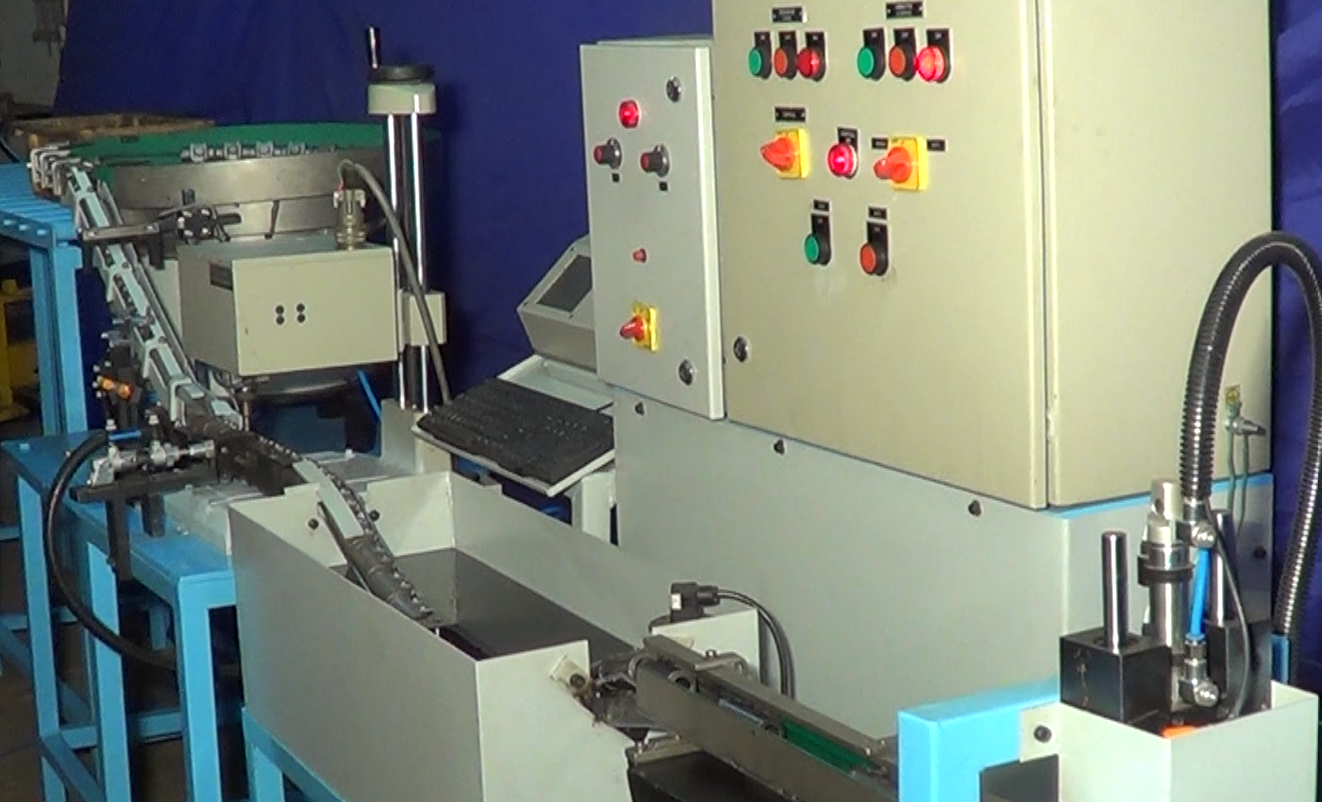

Industrial robots are designed to perform repetitive, high-precision and hazardous tasks in manufacturing and production industries. They are widely used in industries such as automotive, foundries, electronics, metal fabrication, food processing, and pharmaceuticals.

Industrial robots increase productivity, reduce labor costs, enhance product quality, and improve workplace safety by handling dangerous and repetitive tasks.

Benefits:

- High accuracy and repeatability

- 24/7 operation with minimal downtime

- Enhanced process consistency

- Increased productivity

- Integration capability with PLCs and CNC systems

- Reduced labor costs

- Enhanced workplace safety

Areas:

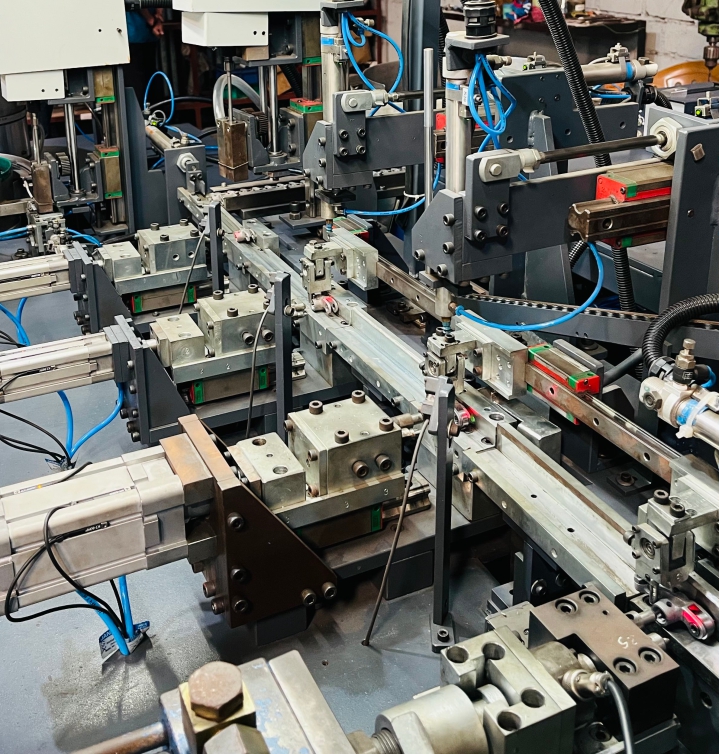

- Machine Tending

- Loading-Unloading of components

- Pick & Place of components

- Welding Applications

- Painting Applications

- Foundry Applications

- Packing and Handling